All Products

High-Quality Purlins, Girts & Eave Struts by Sumiraj

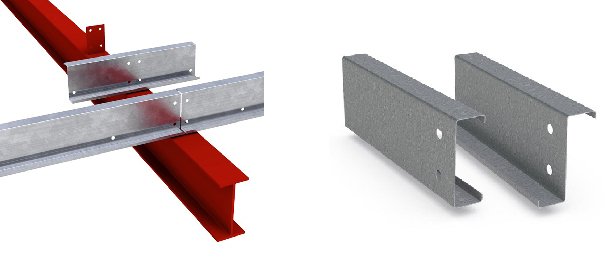

In modern steel construction, structural efficiency and long-term durability depend heavily on secondary framing components such as purlins, girts, and eave struts. These elements play a critical role in supporting roof and wall systems, distributing loads, and enhancing the overall stability of Pre-Engineered Buildings (PEBs).

At Sumiraj, we manufacture high-performance purlins, girts, and eave struts using high-grade steel plates conforming to ASTM A607 Grade 50, ensuring superior strength, consistency, and reliability for industrial, commercial, and infrastructure projects across India.

What Are Purlins, Girts, and Eave Struts?

Purlins

Purlins are horizontal structural members installed along the roof slope. They support roof panels, transfer loads to the main frames, and improve resistance against wind uplift and roof deflection. High-quality purlins are essential for large-span steel buildings and industrial sheds.

Girts

Girts are horizontal wall members that support wall cladding and help resist lateral forces such as wind pressure. Properly designed girts enhance wall stability and ensure long-term performance in varied Indian climatic conditions.

Eave Struts

Eave struts are positioned at the junction of roof and wall. They provide support to both roof purlins and wall girts, ensuring a strong transition point and better load distribution at the eaves.

Material Specification & Manufacturing Standards

All purlins, girts, and eave struts manufactured by Sumiraj are produced from ASTM A607 Grade 50 steel, known for its high yield strength and excellent formability.

Key Specifications:

-

Steel Grade: ASTM A607 Grade 50

-

Thickness Range: 1.0 mm to 3.0 mm

-

Depth Range: 70 mm to 300 mm

-

Manufacturing Process: Precision roll-forming for dimensional accuracy

-

Quality Control: Consistent checks at every production stage

These specifications ensure structural safety, reduced material wastage, and compatibility with modern PEB designs.

Protective Painting & Surface Finish

To enhance corrosion resistance and extend service life, all components are factory painted with a minimum 40 microns (DFT) of primer as standard.

Coating Options:

-

Standard primer coating (40 microns DFT)

-

Custom paint systems as per customer requirements

-

Suitable for diverse environments including industrial, coastal, and semi-urban locations

This protective coating minimizes maintenance costs and ensures long-term durability, especially in Indian weather conditions.

Applications Across Indian Industries

Sumiraj purlins, girts, and eave struts are widely used in:

-

Industrial sheds and factories

-

Warehouses and logistics parks

-

Commercial buildings

-

Manufacturing plants

-

Infrastructure and utility structures

-

Agricultural storage buildings

Their adaptability and strength make them ideal for PEB projects in India, where speed of construction and cost efficiency are key factors.

Why Choose Sumiraj for PEB Secondary Members?

Choosing the right manufacturer directly impacts the performance and lifespan of your steel building. Sumiraj stands out due to:

-

Use of certified high-grade steel

-

Precise thickness and depth customization

-

Uniform factory-controlled painting

-

Compliance with international standards

-

Proven expertise in PEB manufacturing in India

Our system-oriented approach ensures consistency, faster delivery, and dependable structural performance.

Benefits of High-Grade Purlins, Girts & Eave Struts

-

Improved load-carrying capacity

-

Reduced overall steel weight

-

Enhanced corrosion resistance

-

Faster installation at site

-

Lower lifecycle maintenance costs

-

Long-term structural reliability

These benefits directly contribute to efficient and economical steel building solutions.

Trusted PEB Manufacturer in India

Frequently Asked Questions (FAQ)

1. What steel grade is used for Sumiraj purlins and girts?

All purlins, girts, and eave struts are manufactured using ASTM A607 Grade 50 steel, ensuring high strength and durability.

2. What thickness options are available?

We offer thicknesses ranging from 1.0 mm to 3.0 mm, depending on structural design requirements.

3. What is the standard paint coating?

A minimum 40 microns (DFT) primer coating is applied as standard. Custom paint systems are also available.

4. Are custom sizes and depths available?

Yes, we manufacture components with depths ranging from 70 mm to 300 mm, and customization is available as per project needs.

5. Are these suitable for Indian climatic conditions?

Absolutely. Our products are designed to perform reliably in diverse Indian environments, including high heat, humidity, and industrial zones.

Conclusion

High-quality purlins, girts, and eave struts are essential for the safety, durability, and efficiency of steel buildings. With certified materials, precise manufacturing, and robust surface protection, Sumiraj delivers dependable secondary framing solutions that meet modern construction demands in India.

If you are planning a Pre-Engineered Building project and require reliable steel components, choosing Sumiraj ensures quality, performance, and long-term value.